Beyond the Hangar: A Day in the Life of an Airplane Mechanic

The day for an airplane mechanic typically begins with a morning briefing. This gathering serves as a platform for mechanics to discuss the work schedule, review safety protocols, and identify specific aircraft that require attention. Safety is paramount in aviation, and mechanics are rigorously trained to prioritize it at every stage of their work. During these meetings, they also evaluate any outstanding issues reported from previous flights. For instance, if a pilot noted an irregularity with the landing gear during their last approach, the mechanic would ensure that this issue is addressed during the inspection. Following the briefing, the first task often involves a thorough safety check of the aircraft. This process includes inspecting the exterior for visible damage, checking fluid levels, and verifying that all components are functioning correctly. A mechanic might examine the landing gear, ensuring it operates smoothly and is free from signs of wear. This initial inspection not only establishes the tone for the day but also dictates the complexity of tasks that will follow.

Diverse Tasks and Responsibilities

As the day unfolds, airplane mechanics engage in a variety of tasks, each requiring a unique skill set and depth of knowledge. Many mechanics specialize in specific areas, such as airframe, powerplant, or avionics. An airframe mechanic might focus on the aircraft's structural integrity, ensuring that all panels and fuselage sections are intact and safe. Conversely, an avionics technician would concentrate on the electrical systems and navigation instruments, troubleshooting and repairing any discrepancies. Routine maintenance checks are a common aspect of their job, which may include changing oil, replacing filters, and inspecting engines. For example, a mechanic might be assigned the task of replacing a faulty fuel pump, requiring both technical prowess and problem-solving abilities. Meticulous record-keeping is essential, as all maintenance performed must be logged accurately, adhering to strict aviation regulations.

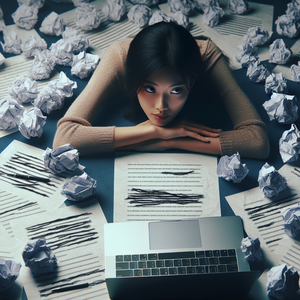

Challenges Faced on the Job

Despite the rewarding nature of their work, airplane mechanics encounter several challenges. One of the most significant hurdles is the pressure of time constraints. Aircraft often operate on tight schedules, and mechanics must work efficiently to ensure that planes are ready for their next flight. This urgency can result in long hours and the need for quick decision-making, which can induce stress. Additionally, the physical demands of the job cannot be overlooked. Mechanics frequently work in confined spaces, on ladders, or at various heights, which can be taxing on the body. Outdoor maintenance work further complicates matters, as they must contend with varying weather conditions, necessitating the use of safety gear and protective equipment. Nonetheless, the physicality of the job can take a toll on their well-being.

Impact on Earning Potential

The diverse skill set and responsibilities of airplane mechanics significantly influence their earning potential. Additional certifications or specialization in high-demand areas, such as avionics or jet engines, can lead to higher salaries. According to the Bureau of Labor Statistics, the median annual wage for aircraft and avionics mechanics was around $66,000 as of 2022. However, this figure can vary widely based on experience, geographical location, and the specific employer. As the aviation industry continues to expand, the demand for skilled mechanics is expected to rise. This growth opens avenues for mechanics to advance into supervisory or managerial roles, which can further increase their earning potential. Those who invest in continual education and training can position themselves favorably in a competitive job market.

The life of an airplane mechanic is a compelling blend of technical expertise, problem-solving skills, and physical endurance. A typical day reveals how these professionals are integral to the aviation industry, engaging in a variety of tasks that ensure safety and efficiency. While challenges such as time constraints and physical demands exist, the rewards—both in job satisfaction and earning potential—make this career path appealing for those with a passion for aviation. By understanding the daily experiences of airplane mechanics, we can truly appreciate the critical role they play in keeping our skies safe and our aircraft soaring. Their work goes far beyond the hangar, forming the backbone of the aviation industry and ensuring that millions of passengers can travel safely around the globe.

Avionics Technician

Airlines such as Delta or Southwest, aerospace manufacturers like Boeing or Lockheed Martin

Core Responsibilities

Diagnose and repair aircraft electronic systems, including navigation, communication, and flight control systems.

Perform routine inspections and ensure compliance with aviation regulations and standards.

Collaborate with engineers to troubleshoot complex avionics issues and implement upgrades.

Required Skills

Proficiency in reading schematics and electrical diagrams.

Strong understanding of aviation electronics and troubleshooting techniques.

Certification from an FAA-approved program or equivalent experience.

Aircraft Maintenance Supervisor

Aviation maintenance companies, commercial airlines, and freight carriers

Core Responsibilities

Oversee a team of mechanics, ensuring compliance with safety protocols and regulatory standards.

Manage maintenance schedules, ensuring timely completion of inspections and repairs.

Conduct training sessions for staff on the latest technologies and safety practices.

Required Skills

Strong leadership and communication abilities.

Extensive knowledge of FAA regulations and maintenance practices.

Previous experience as an aircraft mechanic with supervisory experience preferred.

Powerplant Mechanic

Airlines, charter services, and aircraft manufacturing firms

Core Responsibilities

Inspect, repair, and maintain aircraft engines and propulsion systems.

Conduct engine performance tests and analyze data to identify issues.

Document maintenance and repair activities according to FAA regulations.

Required Skills

Strong mechanical aptitude with a focus on engine systems.

Familiarity with turbine and piston engines, along with relevant diagnostic tools.

Certification as an Airframe and Powerplant (A&P) mechanic is essential.

Airframe Mechanic

Major airlines, military aviation units, and private aircraft service companies

Core Responsibilities

Inspect and repair aircraft structures, including fuselage, wings, and landing gear.

Perform routine maintenance tasks such as corrosion control and surface repair.

Work closely with other technicians and engineers to ensure structural integrity and safety.

Required Skills

In-depth knowledge of aircraft structural components and materials.

Proficiency in using hand tools and specialized equipment for repairs.

A valid A&P license or equivalent certification is typically required.

Quality Control Inspector (Aviation)

Aviation regulatory bodies, maintenance repair organizations (MROs), and airlines

Core Responsibilities

Examine aircraft maintenance and repair work to ensure compliance with industry standards.

Conduct audits of maintenance records and practices, identifying areas for improvement.

Collaborate with mechanics and management to address quality issues and implement corrective measures.

Required Skills

Strong attention to detail and a thorough understanding of FAA regulations.

Experience in aircraft maintenance and familiarity with quality assurance processes.

Certification in quality control or related fields can enhance job prospects.