The Factory Floor of 2050: A Vision of Human-Machine Collaboration in Manufacturing

By 2050, the factory floor as we know it will be unrecognizable. Imagine a sleek, ultra-efficient workspace filled with intelligent robots and interconnected systems navigating seamlessly alongside human workers. In this future, robots will excel in tasks requiring speed, precision, and repetition, while humans will focus on creativity, ethical decision-making, and problem-solving. The factory floor will no longer function as a rigid assembly line but as a fluid, adaptive ecosystem where human-machine collaboration thrives. A key driver of this transformation will be the widespread integration of machine learning and predictive analytics. Manufacturing systems will be equipped to diagnose issues, predict maintenance needs, and propose process optimizations in real-time. These systems will not only learn and adapt to new challenges but also provide actionable insights to human overseers, who will refine and enhance these processes. Notably, while machines will excel at executing tasks, humans will remain at the center of innovation and strategic decision-making, ensuring ethical oversight and addressing complexities that machines cannot resolve autonomously. For example, in an aerospace manufacturing facility, robotic arms equipped with AI might assemble intricate components with unparalleled precision while humans monitor the overall process, troubleshoot anomalies, and identify opportunities for improvement. This partnership will redefine factory workflows, emphasizing collaboration over competition between humans and machines.

The Evolution of Roles: Humans as Innovators and Orchestrators

The advent of smart factories will fundamentally reshape the roles of workers. Traditional manual labor roles, such as assemblers and fabricators, will evolve into positions that require advanced technical and creative skills. Workers will no longer be limited to assembling parts or managing repetitive tasks; instead, they will become orchestrators of complex manufacturing systems. Their responsibilities will include designing workflows, programming robots, analyzing data, and ensuring seamless machine operation. Consider a scenario where a customer orders a custom-made product. In the factory of 2050, AI systems and robots will handle the physical assembly of the product, but human workers will oversee the design modifications and ensure the final product meets the customer’s specifications. This process will depend on the unique human ability to combine creativity, critical thinking, and emotional intelligence. Workers will act as architects of innovation, ensuring that the manufacturing process is not only efficient but also tailored to the needs of diverse consumers. This shift toward human-machine collaboration will also enable the production of highly personalized goods at scale. Unlike the standardized, one-size-fits-all approach of traditional manufacturing, the factory of the future will prioritize customization and flexibility. For example, a human worker might collaborate with AI to design and produce a bespoke piece of furniture, addressing a customer’s specific preferences for size, color, and functionality. This blending of human insight and robotic precision will unlock new possibilities for creativity and efficiency.

The Impact of 3D Printing and On-Demand Production

One of the most transformative technologies on the factory floor of 2050 will be 3D printing. Already making waves in industries such as healthcare, aerospace, and automotive, 3D printing is poised to revolutionize manufacturing by enabling the creation of complex, customized components directly on-site. By 2050, this technology will likely be ubiquitous, allowing manufacturers to produce goods with unprecedented speed, cost efficiency, and minimal waste. For instance, imagine an automotive factory in 2050 that uses 3D printing to produce custom car parts tailored to individual customer needs. A customer might order a car with a specific type of dashboard or a unique exterior design, and the factory could print these components on-demand. Human workers would play a critical role in overseeing the quality and functionality of these parts, troubleshooting any design flaws, and ensuring the final assembly meets safety and performance standards. The integration of 3D printing into manufacturing will also support sustainability goals by reducing material waste and enabling localized production. Factories of the future may no longer need to stockpile large inventories of parts, as components can be printed only when needed. This shift toward on-demand production will not only enhance efficiency but also minimize the environmental impact of manufacturing, paving the way for a greener future.

Skills for the Factory Worker of the Future

As the factory floor evolves, so too will the skills required of its workforce. In 2050, technical expertise will be paramount. Workers will need to be proficient in programming, robotics, AI management, and data analysis. Understanding how to interpret machine-generated insights and translate them into actionable strategies will be a critical competency. Equally important will be the development of soft skills such as communication, adaptability, and teamwork. As human workers collaborate with machines and with one another in increasingly specialized roles, their ability to navigate complex interpersonal and technological interactions will become a defining characteristic of success. Lifelong learning will be essential, with workers regularly updating their skills through training programs, certifications, and on-the-job experiences. For example, a factory worker in 2050 might transition from operating machinery to managing a team of robots. To succeed in this role, they would need both technical knowledge and the ability to communicate effectively with engineers, designers, and other stakeholders. This combination of technical and interpersonal skills will distinguish the workers of the future from their predecessors.

Challenges and Ethical Considerations

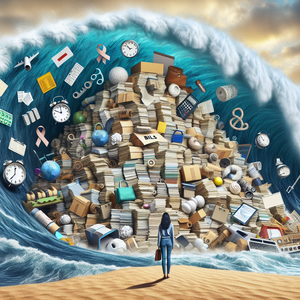

Despite its promise, the factory floor of 2050 will face significant challenges. One of the most pressing concerns is the potential displacement of workers due to automation. As machines take over repetitive tasks, certain jobs may disappear entirely, raising concerns about economic inequality and social disruption. To address this issue, governments, industries, and educational institutions must work together to create robust retraining programs and pathways for workers to transition into higher-skill roles. Ethical considerations will also play a critical role in shaping the future of manufacturing. As AI systems take on greater responsibilities, questions about accountability and decision-making will emerge. For instance, who is responsible if an AI-driven robot makes a mistake that leads to a defective product or a workplace accident? Additionally, ensuring that the data guiding these systems is unbiased and transparent will be essential to maintaining public trust. Human oversight will be indispensable in addressing these challenges and ensuring that technology serves humanity’s best interests.

The factory floor of 2050 represents a bold reimagining of the manufacturing industry. Far from rendering human workers obsolete, automation and AI have the potential to elevate their roles, fostering a harmonious partnership between humans and machines. By blending the precision and efficiency of robotics with the creativity and ethical judgment of humans, the factories of the future will achieve remarkable feats of innovation and productivity. To realize this vision, we must embrace the opportunities and challenges that lie ahead with foresight and adaptability. Investments in education, training, and ethical governance will be crucial to ensuring that the benefits of this transformation are shared widely. Ultimately, the factory of 2050 will not be defined by the dominance of machines but by the strength of human-machine collaboration—a partnership that has the power to reshape manufacturing and redefine the very nature of work.

Industrial Robotics Engineer

ABB, FANUC, Siemens

Job Description

Design, program, and maintain robotic systems used in manufacturing processes.

Collaborate with production teams to integrate robots into workflows, ensuring seamless operation alongside human workers.

Troubleshoot and optimize robotic systems to improve precision, efficiency, and uptime.

Skills

Proficiency in programming languages such as Python or C++.

Experience with robotics frameworks like ROS (Robot Operating System).

Smart Factory Systems Architect

General Electric, Bosch, Schneider Electric

Job Description

Develop and implement the digital infrastructure for interconnected manufacturing systems.

Integrate IoT devices, machine learning models, and predictive analytics into factory operations to enable real-time monitoring and decision-making.

Ensure cybersecurity and data integrity across all systems and devices.

Skills

Expertise in cloud platforms.

Knowledge of industrial IoT protocols (e.g., MQTT).

Experience with edge computing.

Additive Manufacturing Specialist (3D Printing Expert)

Stratasys, HP, Formlabs

Job Description

Manage 3D printing processes to produce customized, on-demand components with minimal waste.

Collaborate with designers and engineers to translate 3D models into viable manufacturing plans.

Oversee quality assurance for printed parts, ensuring they meet safety and performance standards.

Skills

Proficiency in CAD software (e.g., SolidWorks).

Knowledge of materials science.

Experience with various additive manufacturing techniques such as SLA or SLS.

Human-Machine Collaboration Strategist

Amazon, Tesla, Boeing

Job Description

Design workflows and processes that promote effective collaboration between human workers and automated systems.

Analyze task allocation to optimize productivity, ensuring that robots handle repetitive tasks while humans focus on creative and strategic functions.

Train employees to interact effectively with robotics and AI systems in day-to-day operations.

Skills

Expertise in ergonomics.

Knowledge of human factors engineering.

Experience in change management in industrial settings.

Sustainability Officer – Manufacturing

Unilever, Patagonia, Siemens Energy

Job Description

Develop and implement strategies to minimize the environmental impact of manufacturing processes, including waste reduction and energy efficiency initiatives.

Collaborate with engineers to incorporate sustainable materials and design principles into production workflows.

Leverage technologies such as 3D printing to enable localized, on-demand production that reduces supply chain emissions.

Skills

Knowledge of life cycle assessment (LCA).

Understanding of circular economy principles.

Familiarity with compliance with environmental regulations (e.g., ISO 14001).